Xiang'an Subsea Tunnel Roof Sewage Pump (Xiamen, China)

Release time

:2024-01-05 13:35:03 Views:

Project Start Date: November of 2017

Project Location: Xiang'an Subsea Tunnel Xiamen, China, 361000

Project Scope: Municipal Facilities

Total Construction Area: 252.08 m2 (Over 2,713.36 sqft)

Project Overview:

The Xiang'an Subsea tunnel is a critical subsea tunnel connecting Xiamen Island and Xiang'an District, with an approximate total length of 9 km (~ 5.59 miles). The Xiang'an Subsea tunnel is equipped with advanced drainage and ventilation systems to allow safe, robust, and efficient operation under challenging and complex conditions. Among these systems, the roof sewage pump is also integrated into the system and it is responsible for promptly removing accumulated sewage and rainwater from the tunnel's roof, preventing the rising water levels from impacting the traffic. The system is well designed and thoroughly developed with the feature of an automatic start-stop function that can adjust its operation according to the water levels, ensuring continuous dryness and safe operation within the tunnel.

Project Details:

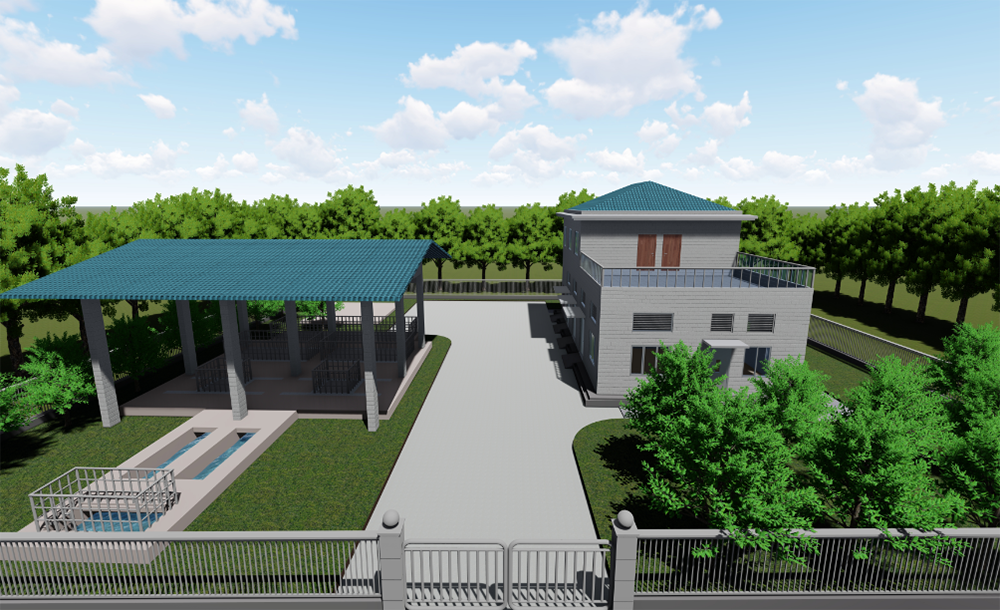

Bimodeling utilized the BIM technology to complete the 3D visualization and modeling for the Xiang'an Subsea tunnel project, providing in-depth views of the tunnel design for the construction and design team to intuitively comprehend the overall structure and the system layout. Through the error check in the pre-construction phase, Bimodeling effectively identified and corrected potential pitfalls in the design. Additionally, the company conducted an in-depth analysis of the tunnel's MEP (electrical, mechanical, and plumbing) systems for optimizing the system configuration. These measures not only improved construction efficiency but also significantly reduced project costs and ensured the successful completion of the tunnel.

Project Location: Xiang'an Subsea Tunnel Xiamen, China, 361000

Project Scope: Municipal Facilities

Total Construction Area: 252.08 m2 (Over 2,713.36 sqft)

Project Overview:

The Xiang'an Subsea tunnel is a critical subsea tunnel connecting Xiamen Island and Xiang'an District, with an approximate total length of 9 km (~ 5.59 miles). The Xiang'an Subsea tunnel is equipped with advanced drainage and ventilation systems to allow safe, robust, and efficient operation under challenging and complex conditions. Among these systems, the roof sewage pump is also integrated into the system and it is responsible for promptly removing accumulated sewage and rainwater from the tunnel's roof, preventing the rising water levels from impacting the traffic. The system is well designed and thoroughly developed with the feature of an automatic start-stop function that can adjust its operation according to the water levels, ensuring continuous dryness and safe operation within the tunnel.

Project Details:

Bimodeling utilized the BIM technology to complete the 3D visualization and modeling for the Xiang'an Subsea tunnel project, providing in-depth views of the tunnel design for the construction and design team to intuitively comprehend the overall structure and the system layout. Through the error check in the pre-construction phase, Bimodeling effectively identified and corrected potential pitfalls in the design. Additionally, the company conducted an in-depth analysis of the tunnel's MEP (electrical, mechanical, and plumbing) systems for optimizing the system configuration. These measures not only improved construction efficiency but also significantly reduced project costs and ensured the successful completion of the tunnel.